A pipe can be defined as a conduit made of various materials such as metal, plastic, wood, concrete or fiberglass. Pipes and fittings are used to transport liquids, gases, slurries or other particles. A piping system usually consists of many different fittings that are selected depending on the design. Pumps, heat exchangers, valves and tanks are also part of the piping system.

Piping systems are the main artery of industrial processes and play a special role in advancing the activities of most factories and workshops. Pipes and fittings make up a significant portion of the total factory costs, which is equivalent to one-third of the total investment. Fittings located in a confined area pose a major challenge for plumbing and industrial support engineers.

Electrical connections can be considered as the most important elements of any residential, office or industrial building, because they are the main source of energy for the building. The use of electrical pipes has become more common among construction project contractors in the last few years. The first and most important advantage of using these pipes is obtaining peace of mind and safety, which plays a major role in raising the standard of the building. The choice of electrical pipe for industrial, commercial and residential installations depends on the overall structure, applications, power supply voltage, load, appearance and costs. One of the main tasks in this case is to choose a material that fits the pipes and electrical connections well and minimizes the possibility of any problems. Follow the continuation of this article to review some important points in this field and review the best products available in the market.

Achieving a proper system with a pleasing appearance requires a lot of skill. The ducts used must be fully constructed before laying the cables. To prevent damage to the wires, the electrical pipe must be assembled using the best possible connections. Wiring design boxes should be convenient and easily accessible. On the other hand, the pipes must be well supported by the right tools. The angle and distance between the electrical pipes is very important in any case. Also, the flow of the whole system must be mechanically constant. Therefore, all connections to switches, switchboards, control panels, and metal cases must be thoroughly inspected for maximum fit. Most electrical systems in factories are surface mounted.

But in offices and residential buildings where there is a risk of injury, power pipelines are usually located on the ground floor or behind plaster and cement walls. The design and use of electrical piping system is done in such a way as to prevent moisture from penetrating into it. PVC pipes are very suitable for this purpose, because they show high resistance to moisture. Wiring should be done as soon as possible after pouring the plaster so that the drying process does not damage the appearance of the wall.

Metal power pipe

Electrical pipes made of metal are suitable for impact resistance as well as high pressure resistance. These pipes can also hold all the cables in the concrete walls for a long time. These unbreakable pipes usually have a glossy surface and therefore have an attractive appearance.

But as you can guess, the use of metal electrical pipes in electrical systems seems a bit strange. The first problem that arises when using metal pipes is their lack of easy ductility and low flexibility. These pipes require a lot of fittings to bend the piping path and are by no means economical in this regard. Among the other disadvantages of metal pipes can be mentioned the following:

Relatively high corrosion from inside and outside due to vulnerability to oxygen and salts in the soil

High weight, very high difficulty during transport as well as difficult installation

High thermal conductivity and energy loss

Short lifespan (10 to 12 years) and the need for frequent repairs and replacements

High price compared to other pipes

Using metal as a power pipe is not very efficient at the moment, as it will cost you a lot of money during installation and commissioning, as well as during maintenance. Experts in the field of electrical systems are always looking for a suitable solution to secure the wiring of buildings, and it seems that the use of plastic pipes for this purpose is recommended more than any other option.

Plastic power pipe

In recent years, the use of plastics in various industries has increased significantly. Plastics such as pvc pipes are not exposed to water, acids, oxidants, oils, soil moisture, fungi and bacteria and can be buried in concrete or plaster for a long time. In general, plastics have lower heat and flame resistance and lower mechanical strength than metals such as steel.

Plastics are not electrically conductive, which in turn can provide greater security when working with them. Most plastic electrical pipes are easy to cut and can be bent when heated slowly. Likewise, plastic fittings are cheaper than metal fittings and can be installed as easily as possible. Most manufacturers also use different plastics to make large size pipes.

UPVC pipe is considered as an ideal material for making power pipe, pool pipe and pressure pipe (under pressure) due to its high resistance to electric current, chemicals as well as moisture. Because UPVC does not use emollients, their hardness is higher than PVC. Interestingly, the lifespan of pipes made of UPVC will in most cases be more than 50 years.

There are many categories for electrical pipes, each of which is used according to customer needs and type of application. The specifications of electrical pipes according to the standards set in Iran are as follows:

| Outer diameter (mm) | Wall thickness | Weight (kg / m) |

|---|---|---|

| ۱۸ | ۰.۱۵ ± ۱.۲ | ۰.۵۳ |

| ۲۰.۴ | ۰.۱۵ ± ۱.۲ | ۰.۵۹ |

| ۲۲.۲ | ۰.۱۵ ± ۱.۲ | ۰.۶۵ |

Cold bent pipe

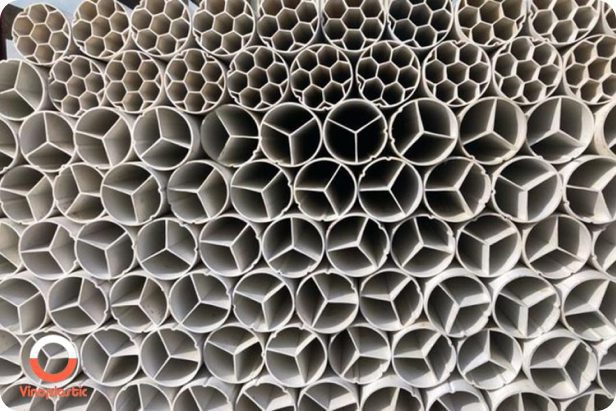

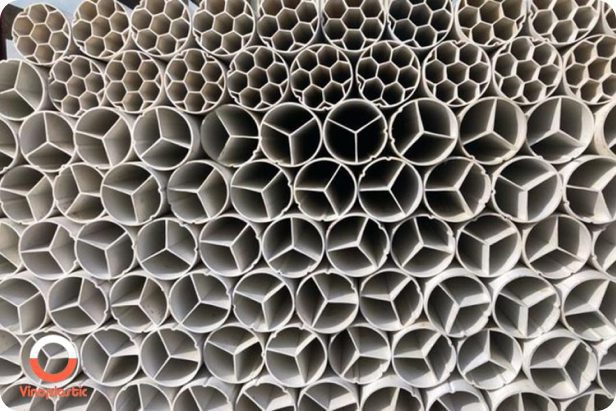

Cold bending pipe is one of the popular products of Vinoplastik Company, which is made using PVC material and according to the national regulations of the Standard Organization of Iran. Many plastic pipes, such as polyamide and polyethylene, ignite easily in the fire and should not be accessed under any circumstances. Many years ago, the National Building Regulations Organization of Iran banned the use of these materials to build electrical pipes.

Vinoplastic cold bent power pipe has different physical and chemical properties that make this product efficient for widespread use. These pipes have a great variety of colors to make it easier to detect power lines, telecommunications, fire alarm network, etc. The resistance of these tubes to flame spread due to their extinguishing properties is well established. Likewise, cold bending electrical pipe is very resistant to shocks, abrasion, corrosion and chemicals.

It is worth noting that vinoplastic cold bending power pipe has good elasticity and can be easily bent using a spring. One of the most important features of these pipes is their low coefficient of roughness, which makes their inner surface smooth and polished, and the electric wires are easily moved inside it.

Advantages of Cold Bending Vinoplastic Pipe

The advantages of vinoplastic cold bending electrical pipes compared to different metals are:

Cold bend pipe price

The use of cold-bending power pipes is on the rise, and this is why manufacturers are doing their best to keep their prices constant. In general, the price of a cold bend pipe is determined by factors such as their size, thickness and length. Cold bending pipes can be found in the market in 13.5, 16, 21, 29, and 36 sizes, which are selected according to the project.

Hot bend pipe

The difference between hot and cold bending pipe is that hot bending electric pipe can be made desired by increasing the temperature. These pipes have special springs that are responsible for the maze of wiring lines in different parts of the building. This product is available in different sizes and it is used to insulate electrical cables, municipal water pipe system and also to cover telecommunication cables.

Vinoplastic hot bent power pipe is resistant to very high temperatures and direct sunlight. On the other hand, the rate of erosion of these pipes is very small and the power pipelines will guarantee you for years. The weight of these pipes is very low and they can be easily installed. The country’s standard organization has placed these products in the line of quality and safe materials used in construction projects.

Hot bend pipe price

Like cold bending power pipes, the price of hot bending power pipes depends mainly on factors such as thickness, length and overall size of the pipe. Needless to say, the size of the hot-bending power pipe is less, and the executors of luxurious construction projects often turn to the cold type. Both products in terms of color and design can well satisfy customers.

Vinobond pipe is a brand of electrical pipes that are produced and supplied by Vinoplastik Company. These pipes are used to pass power cables including PG 11, PG 13.5, PG 16, PG 21 and more expensive items including PG 29 and PG 36. Vino Bands are available in four colors: blue, yellow, red and white, and are available in suitable packages.

Traditional power lines could only be joined together using various joints, such as elbows. However, Vinoplastics has introduced WinBond based on cold bent electrical pipes that can be bent using only one spring, thus making their installation much easier. Vinobond pipe has two other main features which are:

Self-extinguishing capability that makes them safe from fire

Very high mechanical resistance to external shocks

Power pipe interface

The design of electrical piping routes is done with great care to provide a proper appearance if the pipes are surface, or otherwise they are not recognizable from under the plaster or concrete. In these cases, the electrical pipe interface plays the role of continuing the path (sticking the two pipes together) or changing the piping path. The bushing can be considered the most widely used electrical pipe connector, which is very similar to the connections used in the building sewer pipe and is only smaller in size.

Power pipe connectors are also available in 45- and 90-degree curves to easily divert piping in different directions. A variety of elbow fittings are also available for electrical piping. Round junction boxes are also used to separate electrical outlets in a variety of ways. Three-way and four-way divider boxes, lids and gate fittings are among the other commonly used connections.

Price of PVC electrical pipe

At present, the Iranian market has a wide variety of products from domestic and foreign brands. The price of products such as hot and cold bent power pipes is determined based on general factors such as standard grade, purity of materials used and the amount of exports and imports.

Vinoplastik Company is one of the largest producers of PVC and UPVC based products in the Iranian market, which offers its products to our dear compatriots at a reasonable price. Vinoplastic also produces a variety of electrical pipe fittings such as subduct pipes and fork clamps with excellent quality so that you can have the least hassle when installing electrical pipes.

The building’s electrical plumbing must be very sensitive, as most of it is usually buried under a mass of plaster or concrete, and it will not be desirable to replace it in any way. You have the opportunity to contact vinoplastics consultants and let them know the details of your project. Our consultants will introduce the best possible option to you after presenting the possible cases.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Egestas purus viverra accumsan in nisl nisi. Arcu cursus vitae congue mauris rhoncus aenean vel elit scelerisque. In egestas erat imperdiet sed euismod nisi porta lorem mollis. Morbi tristique senectus et netus. Mattis pellentesque id nibh tortor id aliquet lectus proin. Sapien faucibus et molestie ac feugiat sed lectus vestibulum. Ullamcorper velit sed ullamcorper morbi tincidunt ornare massa eget. Dictum varius duis at consectetur lorem. Nisi vitae suscipit tellus mauris a diam maecenas sed enim.